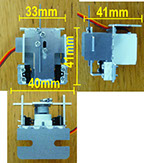

The Ultimate in Servo Mounts

Dingo Servo Micro 10 V2 (B)

The new Micro 10 V2B incorporates many features that have been developed

over the past few years and have been well tested in the Micro 10 mount.

Two improvements have been made following on from customer feedback.

Improvements like: Slotting the switch mounting holes to the edge of the frame

to allow easier fitting of switches and easier removal

for replacement or repairs.

Creating more space between the horn and slider.

Changing the drive screw Ver 2B only

Features Like: Tapped holes for motor mounting, Improved switch operation

Reduced height under the baseboard and simplified

actuator adjustment.

The ability to operate up to 4 microswitches.

(2 switches supplied in kit)

Perfectly linear motion for point operation.

Will fit most 9g servos like PowerHD 1900A, Fitec FS90 or

TowerPro SG90 / MG90

The Micro 10 V2 is a direct replacement for our very popular Micro8 / Micro10

and uses the same drill jig for setting out.

Please Note : Servo motor and control circuitry not included. In the kit.

To contact us:

David Ingoldby

Phone: +44(0) 7754901324

E-mail: dingoservo@gmail.com

www.dingoservo.co.uk

The Micro 10 V2 is an updated version of our flagship Servo Mount

for the operation of points on model railways.

It can throw up to 10mm and as such can be used on most model gauges from O to Z

It is a direct replacement for the Micro8.

Downloads

Product List

Contact Us

Video Links

Price List and

Order info.

As the Micro 10 V2 is a direct replacement for the Micro8, the Micro 8 drill jig can be used to help align fixing holes on this particular mount.

Full instructions for use on the Downloads Page.

The New Micro 10 V2 will also be available in Multipacks.

Trouble shooting.

There have been a few users which have had an issue regarding the lower Actuator pin tightening screw fouling on the motor horn.

It would appear that there are some variations in the sizes of the servo motors and very occasionally this creates the problem.

There are 3 simple fixes.

1. File the offending screw down slightly.

2. Fit a small M2 washer under the screw head.

3. Fit a thin paper washer between the servo motor and the main frame.

Either of these will allow the horn to move freely.

(Thanks to Don Ramsey for the pic)

Note: This has been sorted out by moving the slider by 0.5mm on the new Version 2

A second issue found is that if you are using a large movement on the mount you may need to trim a bit off the horn to prevent it from fouling the wings on the frame.

Note: Multipacks do NOT contain switches, Nut Plates and the M2x10mm screws.